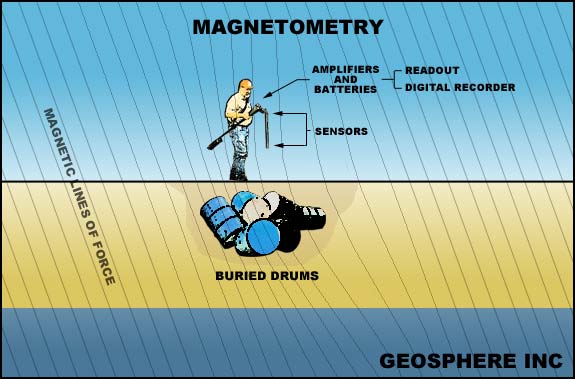

Simplified

illustration of detecting an anomaly in the Earth's magnetic field caused by

buried steel drums (in the northern United States, facing west).

A

magnetometer detects local buried iron objects because the object causes the

(locally) uniform magnetic field of the Earth to strengthen or weaken

depending on the size, orientation, and magnetic characteristics of the object.

Most of the normal field distortion is the result of an induction effect on

the earth's magnetic field by that particular iron object; however, many objects

may have a residual permanent magnetism which may interact with the induced

field, affecting the magnitude of the overall magnetic anomaly. These

variations coupled with variations in the object's orientation with respect

to the earth's field (as well as the state of corrosion of the object)

make absolute calibration for certain sized targets difficult, if not impossible.

Obtaining relative changes across the site are far more important than obtaining

absolute values. In addition, due to the weakening or strengthening effect

of the object on the (locally) uniform magnetic field of the Earth, a response

over one target produces both positive and negative distortions; such

data can yield very complicated contour maps. Oftentimes, to increase

the map's readability, these contour maps are converted to anomaly maps with

shading patterns used to distinguish two or more levels of anomaly magnitude.

On the other hand, large masses of drums may be detected easily to depths of

10-40 feet. The magnetometer can only sense ferrous materials such as

iron and steel; other metals like copper, tin, aluminum,

and brass are not ferromagnetic and cannot be located with a magnetometer

(but may be found with a metal detector).

Several different types of magnetometers are available. Some require the

operator to stop and take discrete measurements (by positioning the instrument

and pressing a button) which are compared to a base station reading; these systems

are generally proton magnetometers. Fluxgate magnetometers permit

the acquisition of data continuously as it is carried across the site.

The continuous coverage is obviously more suitable for mapping complex and large

burial sites. The effectiveness of magnetometer results can be reduced

or inhibited by interference (noise) from time-variable changes in the earth's

field and spatial variations caused by magnetic minerals in the soil or iron

debris, pipes, fences, buildings and vehicles. Many of these problems

can be minimized by careful selection of the type of instrument and field procedures

used for the survey.

For example, the gradiometer configuration (two sensors mounted vertically)

was designed to overcome large scale diurnal intensity changes in the earth's

magnetic

field; this design may also be used to minimize the lateral effects of nearby

fences, buildings, etc. Without the need for a base station, the gradiometer

permits the operator to concentrate on specific areas or targets of interest.

Because of these operational advantages, Geosphere

generally employs a highly sensitive fluxgate gradiometer system for most surveys.

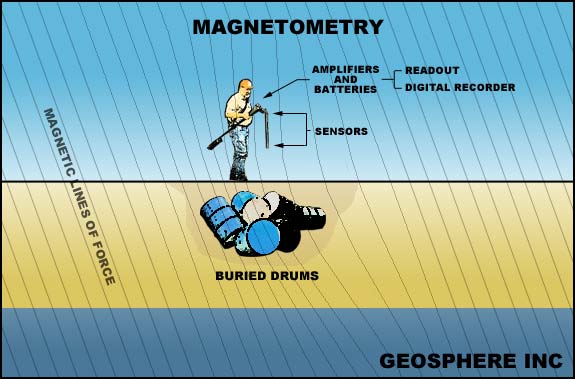

Looking

for more drums beneath the surface with the magnetometer

Magnetometers

measure variations in the magnetic field of the earth. Whether on the

surface or below, iron objects or minerals cause local distortions or

anomalies in this field. Originally designed for mineral exploration,

magnetometers are now used in the environmental field for locating buried steel

drums, tanks, pipes, and iron debris in trenches and landfills.

A magnetometer's response is proportional to the mass of iron in the

target. In a relatively "clean" area, a single drum may be theoretically

detected to a depth of 20 feet from the surface. In practice, however,

numerous smaller, near-surface iron objects will obscure the weak deeper target.

A more realistic maximum depth of detection is 5-10 feet.

email:

consultants@geosphereinc.com

124 north auburn road auburn, mi 48611 tel: (989) 662-6149

fax: (989) 662-7701

copyright ©1990-2007 geosphere inc

![]()